Anthracite Coal

IGR manages the entire supply chain for anthracite coal, from source to the point of delivery. This includes procurement ex-factory, on-road transportation, port handling, financing and storage.

IGR understands that, prior to making large financial commitments on anthracite coal, especially in situations where companies plan to substitute a percentage of metallurgical coke input with anthracite coal, some companies prefer to test the anthracite coal material in smaller batches. IGR has successfully provided anthracite coal packaged in bulk bags, loaded into containers and delivered to the port of choice.

IGR Anthracite Coal supplies are authenticated by an independent assayer. The entire loading process is overseen by our inspectors at the load ports.

Over time IGR has positioned itself as a timely and cost-effective provider of different grades and sizes of coal and coke from the best producing regions in the world, via alliances and partnerships with well-established, and innovative coal miners and coke manufacturers.

IGR manages the entire supply chain for anthracite coal, from source to the point of delivery. This includes procurement ex-factory, on-road transportation, port handling, financing and storage.

IGR understands that, prior to making large financial commitments on anthracite coal, especially in situations where companies plan to substitute a percentage of metallurgical coke input with anthracite coal, some companies prefer to test the anthracite coal material in smaller batches. IGR has successfully provided anthracite coal packaged in bulk bags, loaded into containers and delivered to the port of choice.

IGR Anthracite Coal supplies are authenticated by an independent assayer. The entire loading process is overseen by our inspectors at the load ports.

Cost saving strategies with anthracite

Anthracite coal gives most energy and least pollution. It is inherently a high carbon source that is almost made entirely of carbon and is used in the metal smelting and fabrication industries, including steel manufacturing. It is the best and the cleanest type of coal to use that improves the life and efficiencies of smelters, blast furnaces and power plants.

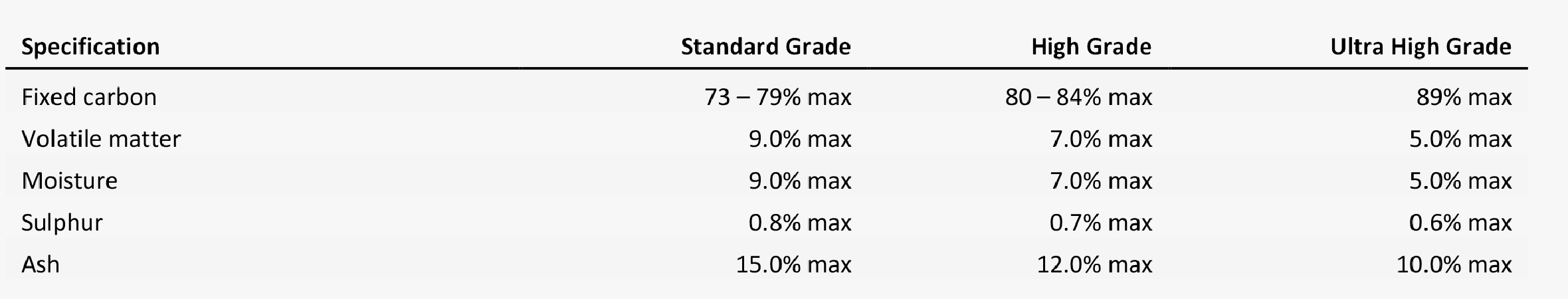

In blast furnaces and smelters, ultra high-grade anthracite coal (egg, stove, chestnut and pea), low in VM, sulphur, alkali and phosphorous can replace a percentage of metallurgical coke, leading to significant annual cost savings of up to 40%.

In sinter plants, anthracite coal low in sulphur and VM can replace breeze coke and petroleum coke.

In recarburizer, high quality anthracite coal can replace coke or synthetic graphite.

In electric arc furnace, anthracite coal is used as injection coal to foam slag. Controlled foam slag improves the coupling behaviour of the arc and prolongs service life of the furnace lining.

IGR Anthracite Coal Sources

IGR sources anthracite from USA, Canada South Africa, Russia and Vietnam. While China remains the largest producer of standard grade anthracite coal, due to export restrictions of anthracite, it is difficult to get reliable sources who are able to commit and deliver. North Korea is another large producer of anthracite coal, but trade restrictions and political pressure are deterrents. Anthracite deposits also exists in Peru but of lower quality.

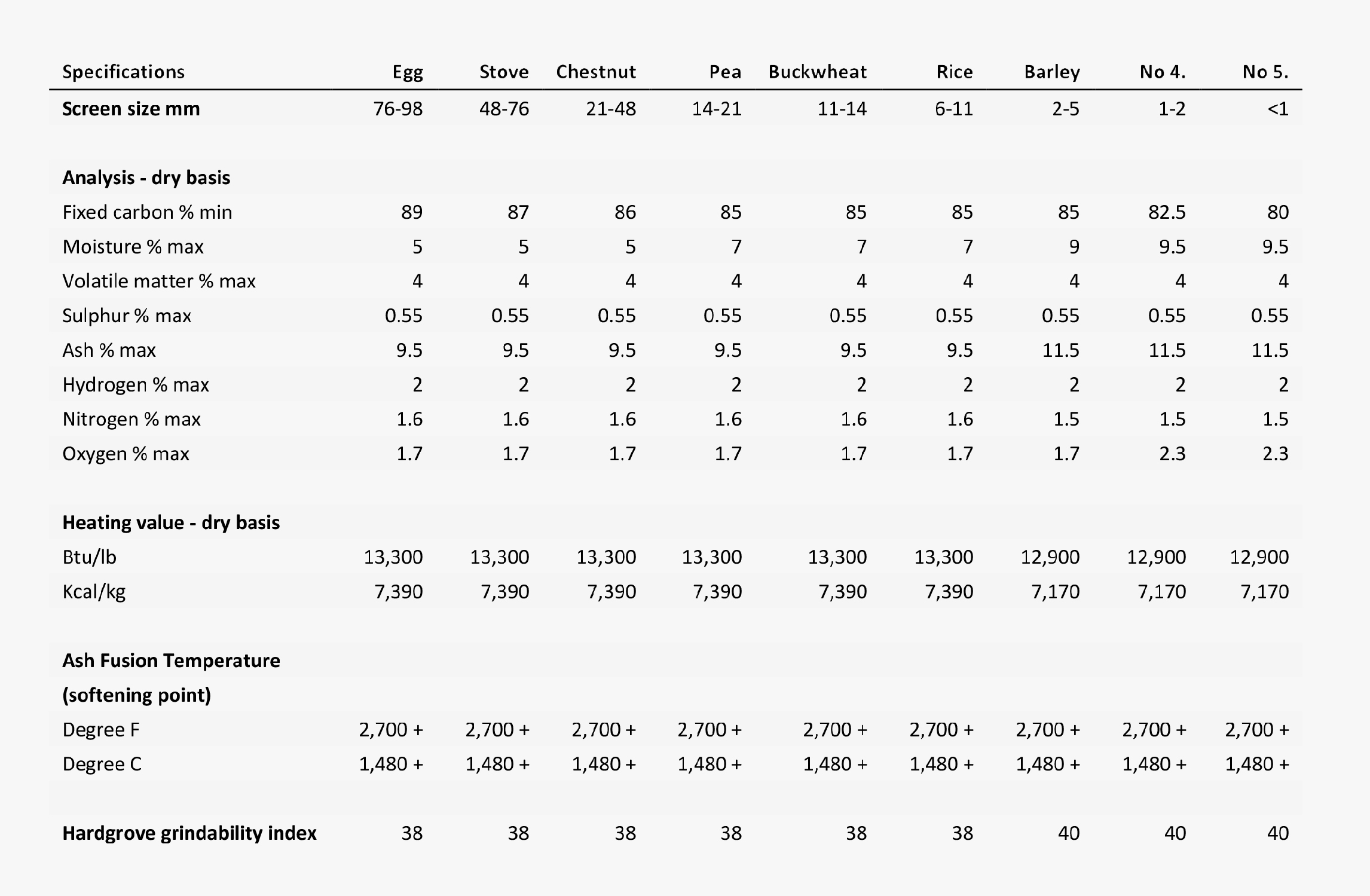

Note: Modified high carbon and blended sizes available upon request